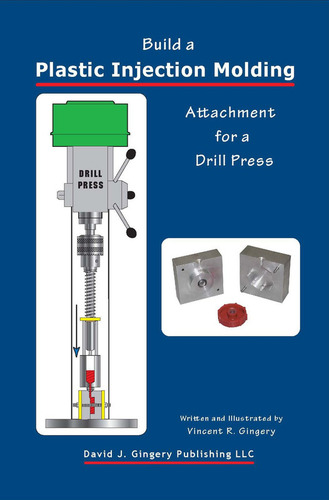

Build A Plastic Injection Molding Attachment For Drill Press

en 12 cuotas de sin interés

Solo en Santiago de Chile

Comprando dentro de las próximas 5 h 58 min

¡Última disponible!

+10mil ventas

Lea+

Tienda oficial de Mercado Libre

+500 Seguidores

+10mil Productos

MercadoLíder Platinum

¡Uno de los mejores del sitio!

+10mil

Ventas concretadas

Brinda buena atención

Entrega sus productos a tiempo

Medios de pago

Características del producto

Características principales

Autor | Vincent Gingery |

|---|---|

Idioma | Inglés |

Editorial del libro | David Gingery |

Tapa del libro | Blanda |

Con índice | Sí |

Año de publicación | 2007 |

Otros

Cantidad de páginas | 48 |

|---|---|

Altura | 21,5 cm |

Ancho | 14 cm |

Peso | 60 g |

Con páginas para colorear | No |

Con realidad aumentada | No |

Género del libro | Ingeniería y Tecnologías |

Tipo de narración | Manual |

Tamaño del libro | Mediano |

Edad mínima recomendada | 18 años |

Escrito en imprenta mayúscula | No |

Cantidad de libros por set | 1 |

Descripción

LIBRERÍA LEA+

For the most part, plastic injection molding today is done with complex automated machinery turning out many thousands of items per day. But what if you are an experimenter, inventor or hobbyist and you just want a few parts made?

We have attempted to answer that question for you by providing these plans for a small hobby size injection molding machine capable of molding slightly more than 1/2 ounce of plastic. (.59 ounce to be exact)

This amazingly compact machine is designed to be used with a floor model style drill press having a minimum spindle travel of 3 inches. Thus, we refer to it as an injection molding attachment for a drill press. The unit itself measures approximately 12 inches long x 1-3/4 inch diameter at its widest point and weighs just 3 pounds. In operation, plastic is melted in the injection barrel of the machine by two 1/4 inch diameter x 2-1/2 inch long cartridge heaters. The temperature of the barrel is accurately controlled by a digital temperature controller and thermocouple arrangement. The force required to inject the plastic is provided by the feed mechanism of a drill press.

Construction is simple and straight forward, but it will require basic metal working knowledge and the ability to operate a metal lathe and a drill press along with other hand and power tools associated with metal working and machine work in general.

Here in this booklet you will receive detailed step by step instructions along with photos and drawings showing how to build your very own injection molding attachment for a drill press. A material list is provided. Suppliers are also identified and you will also receive a basic introduction to plastic injection molding in general.

Before you know it, you will be creating plastic products of your own design. And you will have the capability to cast replacement parts, or even make copies of those hard to find items. The possibilities are indeed endless

----------

¡Cuéntanos si necesitas más libros y podemos publicar un PACK A TU MEDIDA, para que AHORRES en gastos de envío! Necesitamos saber el título y autor para ver disponibilidad.

Preguntas y respuestas

¿Qué quieres saber?

Pregúntale al vendedor

Nadie ha hecho preguntas todavía.

¡Haz la primera!