Uxcell 4 Grifos De Rosca De Flauta En Espiral, Macho De Rosc

en 12 cuotas de sin interés

Disponible 24 días después de tu compra

¡Última disponible!

+1000 ventas

- Tienes 30 días desde que lo recibes.

- Compra ProtegidaSe abrirá en una nueva ventana, recibe el producto que esperabas o te devolvemos tu dinero.

Vendido por LECHUZA STORE

+1000

Ventas concretadas

Brinda buena atención

Entrega sus productos con demora

Medios de pago

Características del producto

Características principales

Marca | Uxcell |

|---|---|

Modelo | Unico |

Color | Black |

Descripción

Bienvenid@,

Traemos lo que quieras, en menos de 25 días hábiles.

TÉRMINOS Y CONDICIONES

------------------------------------------

- Fotos referenciales del producto, consulte no mas

- Despachamos a todo Chile con Starken o Mercado Envios

- Productos traidos de Estados Unidos, es probable que los productos electronicos trabajen en 110V y NO en 220V, podria usar un transformador, para mas informacion primero nos puedes preguntar todas las inquietudes que tengas.

Uxcell 4 grifos de rosca de flauta en espiral, macho de roscar métrico con revestimiento de nitruro M6 x 1, herramienta de roscado de máquina 6542 de acero de alta velocidad totalmente rectificado para reparación de roscas de maquinista

uxcell 4pcs Spiral Flute Thread Taps, M6 x 1 Nitride Coated Metric Screw Tap, Fully Ground High Speed Steel 6542 Machine Tapping Threading Tool for Machinist Thread Repair

COLOR: Black

MODELO: UNICO

MARCA: uxcell

TALLA: M6 x 1

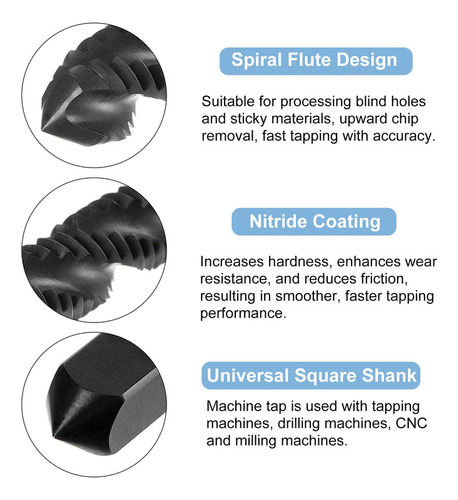

-Metric Spiral Flute Taps: M6 x 1 metric thread, H2 tolerance (accuracy), right hand thread cutting. Spiral flutes are fully ground to provide upward chip removal, with clear threads and sharp cutting edges. Flutes on the screw tap help to remove chips and debris from the hole.

-6542 (M2) High Speed Steel: Run at high speeds and generate threads quickly and efficiently, offering high hardness, wear resistance, and good toughness. Nitride coating increases hardness, enhances wear resistance, and reduces friction for longer service life, resulting in smoother, faster tapping performance.

-Applications: Thread taps are great for processing blind holes and sticky materials. Can be used for drilling and tapping stainless steel, aluminum, alloy steel, ordinary steel, cast iron, non-ferrous metals, hard plastics, etc.

-Machine Tap: Suitable for drill presses, tapping machines, CNC and milling machines. Used with tapping oil to get higher quality threads and more durable taps. Control speed according to material hardness. The higher the hardness, the slower the speed.

-Tips: Machine taps are suggested to be used with tap chucks with overload protection. It is not recommended for hand use and electric drill tapping. The tapping angle should be 90 degrees vertical and stable. The tapping depth should not exceed 1.5 times the diameter of the tap.

:Thread Size: M6 x 1Square Shank Width: 4.4mm / 0.17"Thread Length: 23mm / 0.91"Total Length: 67mm / 2.64"Tolerance: H2 (Accuracy)Material: High Speed Steel 6542 (HSS 6542)Finish: Nitride CoatedManufacturing Process: Fully GroundPackage Content: 4pcs x Spiral Flute Thread TapsDescriptions:1. Metric thread tap features spiral flutes, clear threads without burrs, and right hand thread cutting. Spiral flutes are fully ground to provide upward chip removal. Flutes on the screw tap help to remove chips and debris from the hole.2. 6542 (M2) high speed steel screw taps run at high speeds and generate threads quickly and efficiently, offering high hardness (HRC62-64), wear resistance, and good toughness. Nitride coating increases hardness, enhances wear resistance, and reduces friction for longer service life, resulting in smoother, faster tapping performance.3. Spiral flute tap is suitable for processing blind holes and sticky materials. Used for drilling and tapping stainless steel (below 30HRC), aluminum, die steel, ordinary steel, non-ferrous metals, and hard plastics.4. Machine threading tap is used with drill presses, tapping machines, CNC and milling machines. Used with tapping oil to get higher quality threads and more durable taps. Control speed according to material hardness. The higher the hardness, the slower the speed.5. Machine taps are suggested to be used with tap chucks with overload protection. It is not recommended for hand use and electric drill tapping. The tapping angle should be 90 degrees vertical and stable. The tapping depth should not exceed 1.5 times the diameter of the tap. B0CY2JKGQ5

Garantía del vendedor: 90 días

Preguntas y respuestas

¿Qué quieres saber?

Pregúntale al vendedor

Nadie ha hecho preguntas todavía.

¡Haz la primera!